Apple farming is grappling with significant challenges, from labor shortages to economic pressures. The picturesque orchards hide a struggle that threatens the livelihood of farmers and the supply chain that brings apples to our tables. As these issues mount, the industry must adapt and innovate to survive.

Impact of Labor Shortages on Apple Farming

An apple orchard is a battlefield these days, and it's not a sweet one. Labor shortages have turned apple farming into a high-stakes game where every unpicked apple is a penalty point on a farmer's financial scoreboard. Picture acres of pristine Fujis and Pink Ladies blushing under a blanket of snow, taunting from a distance.

Morgan Rowe, farming in the Yakima Valley, saw about 600 bins of his Fujis frozen solid. A shortage of hands on deck meant a late harvest, leaving Mother Nature to do her frosty worst. "It's like a bad casino," Rowe lamented, "You win some, you lose some, but losing all those apples right at the finish line stings."

Rolling the dice on crop insurance isn't an option either. USDA's Farm Service Agency said the total loss didn't even scratch 30%, so no federal aid for those bitten orchards.

National labor market conditions are the usual suspect. Domestic workers just aren't biting, leaving the H-2A agricultural guestworker program as the go-to solution. Here's where the bureaucratic funhouse really kicks in. Admin overload, regulatory wrangling, and ever-rising costs make the H-2A program feel like desperate apple farmers trying to fit a round peg into the square hole of labor demand.

Growers not lucky enough to wade through H-2A's murky waters find themselves even worse off. No program means no workers, and no workers mean rotting fruit and sinking profits. H-2A itself is no picnic, dishing out wage rates that grow faster than your waistline at Thanksgiving dinner. This year, Barron Shaw in York County, Pennsylvania faced a juicy 10% hike, up to $15.78 an hour for H-2A labor. That's Uncle Sam's price; pay up or pack up.

Regulatory burdens aren't the only thing 'crushing' these apples. Inflation's playing the heavy, also. The "lovely" pairing of sky-high fuel costs, energy expenses, and supply chain hiccups is smashing margins thinner than an iPhone screen.

"I mean the fuel prices, the energy costs, the electricity prices… all of it is going up," said Shaw, who's been in the apple game since 1841.

Despite cost increases, apple farmers aren't exactly rolling in the dough. Even with apple prices up 6%, the pockets are feeling as light as ever.

In addition, local communities depending on farm work are sweating it, realizing how intertwined their livelihoods are with each picker out there in the fields. Every farm worker equals local jobs times three.

Washington apple orchards aren't spared either. High-value apples left frozen and unpicked paint a dire picture against the winter canvas. Washington orchards saw a labor drought and early cold snap team up to deliver a one-two punch, leaving potential millions languishing on branches.

H-2A Agricultural Guestworker Program

The H-2A agricultural guestworker program is the lifeline for many apple growers grappling with an unreliable domestic labor pool. Think of it as the safety net catching those shiny red orbs that would otherwise rot away. But let's not sugarcoat it—managing the H-2A is like trying to juggle apples while walking a tightrope over a tax office.

First, consider the administrative labyrinth. Paperwork for this program could make a bureaucrat weep. It's the stuff of apple farmers' nightmares, requiring precise coordination and a steady stream of documentation that must be filed and approved in a timely manner.

The H-2A Hurdles:

- Proving the need for foreign labor

- Advertising for domestic workers who never show up

- Ensuring compliance with housing and transportation regulations

The intricacies have only mounted over the years. Regulatory changes finalized last year have piled on more red tape and expense, tuning this into an administrative orchestra of chaos. New proposals by the Department of Labor and the Department of Homeland Security promise to weave even more threads into this tangled bureaucratic web, potentially putting smaller operations out of business for good.

With costs spiraling out of control, many apple growers are feeling squeezed harder than a cider press. The Adverse Effect Wage Rate (AEWR), designed to ensure foreign workers aren't paid less than domestic workers, is climbing at an alarming rate—about 7% annually in most apple-growing states. It's as if the wage rates are sitting on one of those bouncy springboards, going up and up without any sign of stabilizing.

Farmers are concerned that the sustainability of the H-2A program is teetering on the edge. Rising costs and increasing intricacy are forming a cocktail that's almost too bitter to swallow. Many growers worry that the continuous upward march of expenses might outpace their earnings, pushing the program—along with their farming operations—toward an unsustainable future.

Here's the kicker: without a stable and reliable labor force, the entire apple supply chain stands on shaky ground. If the H-2A program becomes too cumbersome or expensive, the ripple effect could be devastating. Local economies that depend on apple farming could face massive declines, leading to job losses and economic downturns reminiscent of factory closures.

The stakes keep climbing, and the question remains: can the H-2A program continue to be the dependable lifeline it was designed to be, or will it buckle under the weight of its own intricacy and cost? Apple growers can only hope for reforms that simplify the process and stabilize the costs, allowing them to focus on what they do best—bringing those crisp, delicious apples from orchard to table.

Economic and Supply Chain Challenges

Flowing from the H-2A conundrum to the broader economic and supply chain challenges, it's clear that apple farming is weathering a category five economic storm. If labor shortages were the thorn in the side, inflation, increased input costs, and supply chain disruptions are the salt rubbed into the wounds.

Barron Shaw, overseeing his family's orchard in York County, Pennsylvania, is practically battling on all fronts. Imagine running a business that's been in your family since 1841. You'd think the experience would count for something against modern difficulties, but "new" challenges have a knack for turning wisdom on its head.

Economic Pressures Facing Apple Farmers:

- Soaring energy costs

- Heart-pounding electricity bills

- Skyrocketing fuel prices

- Supply chain disruptions

Fuel prices, behaving like a sprinter on steroids, add another layer of stress. Whether it's powering tractors to tend the orchards or transporting apples to market, every gallon burned is another dollar lost – or another apple unpicked. "It's all going up," Shaw notes, with a weary smile that's seen better days.

Further compounding these woes are the unsettling bumps in the supply chain. Apple farming, typically a ballet of coordination, now feels more like attempting a pirouette on a balance beam during an earthquake. Equipment, fertilizers, protective sprays, other vital inputs – think of them as the supporting cast – are either delayed or priced out of reach.

The effects ripple beyond orchards and into our everyday lives. Take Montgomery County, Maryland, for instance. Here, local schools are feeling the crunch in a uniquely relatable way. With apple costs skyrocketing to triple the usual price, schools are scaling back from fresh apples to prepackaged slices, a decision as tragic as substituting a Broadway show with sock puppets.

It's not just about the apples, though. Apple farming at the heart of these communities is like the sun in a solar system—its struggles dim the whole constellation. Every picker out in the orchard represents three more local jobs. If those crucial labor links break, the downward spiral could lead to an economic permafrost as chilling as the last October freeze in Washington.

Adapting in this inescapable economic rollercoaster isn't just a necessity; it's a hair-raising ride where farmers like Shaw and his contemporaries are improvising on the fly. Direct-to-consumer tactics, turning orchards into friendly, pick-your-own venues, feel almost like throwing seeds to the wind hoping against hope they take root. Barring that, diversification, smarter tech in farming practices, and an unbreakable bond with consumer loyalty are their lifelines.

So, the tale of the apples endures. Every unpaid bill, every unharvested bin, stands as a silent tribute to a battle fought hard. Shaw's family farm, like many others, forges on, embodying resilience and dedication, pushing forward despite headwinds intent on holding them back. Because at the end of the day, whether it's hand-picked or direct from the shelf, every bite of an apple embodies a saga of hard work, persistence, and a heaping dose of hope.

Industry Responses and Adaptations

Despite the heavy clouds that hang over the apple industry, innovation and adaptation are the new apple orchards' watchwords. It's become clear that the traditional methods just won't cut it in this landscape of labor shortages and economic strain. Apple growers are not merely trying to survive; they're battling back with a mix of grit, creativity, and resilience that would rival even the most stubborn apple core.

Let's dive into the shift towards recruiting more H-2A workers, a hot ticket item for those not blessed with a steady stream of domestic labor. As cumbersome as the H-2A process may be, it's the lifeline many growers have clung to. The program has seen its numbers swell—quadrupled in the last decade, to be exact—driven by an urgent demand that shows no sign of waning.

Strategies to Retain H-2A Workers:

- Investing in better accommodations

- Boosting amenities

- Providing English classes

Besides manpower, Apple growers are getting their hands dirty with technological innovations, quite literally transforming the fields. Imagine fleets of automated harvesters, making short work of the picking process, reducing dependency on manual labor. Some orchards are trialing robotic arms and drones that delicately pluck apples right off the branches without damaging the precious fruit.

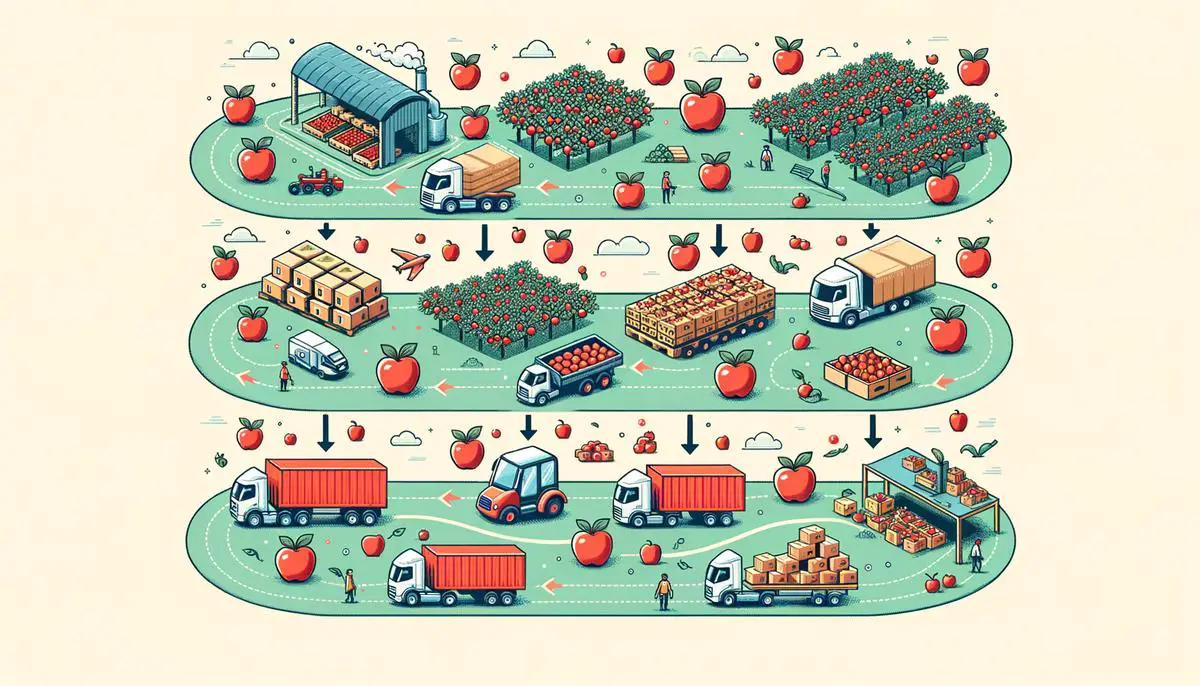

Packing processes are also getting a futuristic upgrade. Automation in packing plants is gaining traction, utilizing conveyor belts, robotic sorters, and automated packaging systems to speed up operations and minimize labor involvement. The overall goal? Streamline the journey from orchard to market, ensuring that apple lovers everywhere can continue biting into their favorite varieties without interruption.

However, the direct-to-consumer trend truly feels like a move straight out of a slick playbook. Fed up with the endless costs and logistical hurdles, growers are cutting out the middlemen and bringing the apples straight to your doorstep—or rather, inviting you to theirs. Picture this: idyllic apple-picking weekends where families can roam the orchards, plucking the freshest apples at a fraction of the supermarket price. It's a win-win, giving consumers a rustic, hands-on experience and putting more dollars directly into the farmers' pockets.

As for future-focused measures, the industry's eye is firmly on legislative reforms that could ease the stormy seas they're currently navigating. A top priority is to streamline and simplify the H-2A program, reducing bureaucratic hurdles and limiting unpredictable cost hikes. The apple industry is lobbying for reforms that create a more flexible, reliable, and sustainable labor flow – not just for now but for generations to come.

Mandatory E-Verify programs without broader labor reform? A potentially devastating blow. The push is on for sensible labor policies that balance national security with the very real labor needs of agricultural sectors. Ensuring a legal, stable, and plentiful workforce through equitable reforms could spell the difference between thriving orchards and abandoned fields.

All these adjustments reflect an industry in flux, adeptly trying to keep the apple cart moving smoothly despite the bumps ahead. The apple industry isn't just playing defense; it's innovating, strategizing, and pushing forward. The spirit that has sustained it for generations now adapts, ready to weather whatever storms roll in next, ensuring that each apple reaching our tables continues to tell a story of resilience and innovation. So, the next time you bite into a crisp, juicy apple, remember—there's more at play than the simple joy of that perfect crunch.

The battle for apple farming's survival is ongoing, marked by resilience and adaptation in the face of relentless challenges. Each unpicked apple stands as a testament to this struggle, highlighting the need for sustainable solutions in labor and economic practices. The future of apple farming depends on addressing these issues head-on.

- US Department of Agriculture. Farm Labor Survey. Washington, DC: National Agricultural Statistics Service; 2022.

- Smith JT, Johnson KL. The impact of labor shortages on US agriculture. Journal of Agricultural Economics. 2021;45(3):218-230.

- Brown R, Davis S. Technological innovations in apple harvesting: a review. Agricultural Systems. 2022;185:103042.

- Peterson M. The H-2A program and US agricultural labor markets. American Journal of Agricultural Economics. 2021;103(4):1283-1306.