Controlled Atmosphere (CA) Storage

Controlled Atmosphere (CA) storage is a clever method to keep apples fresh long after harvest. By reducing oxygen levels from 21% to about 2-3%, growers essentially put apples into hibernation, slowing down their ripening process.

These airtight storage rooms are precisely controlled, with the right balance of:

- Oxygen

- Carbon dioxide

- Temperature

- Humidity

Different apple varieties respond differently to CA storage, with some lasting longer than others.

Apples must be in top condition when they enter CA storage, typically going in on the day they're harvested. The carefully managed environment slows the apples' respiration to a crawl, preserving freshness without any artificial preservatives.

This system ensures we can enjoy crisp, fresh apples even in the depths of winter, long after the fall harvest has passed. It's like a time capsule for apples, keeping them in a state of suspended animation until they're ready to hit the market.

Frost Protection Technologies

Frost protection is crucial for saving apple blossoms from unexpected spring chills. Growers employ various high-tech methods to keep Jack Frost at bay.

Frost Fans

Frost fans are like giant automatic stirrers for the orchard air. When temperatures drop dangerously low, these smart fans kick into action, circulating air to prevent frost from settling on delicate apple blossoms.

Wind Machines

Wind machines, resembling stationary wind turbines, pull warmer air from above down to the trees. They create a protective bubble of warmth around the orchard, shielding vulnerable buds from the cold.

Helicopters

In some cases, helicopters are used as a mobile frost-fighting force. Their rotor blades create a downwash of air, displacing colder ground air and keeping frost away from the buds. It's like an aerial knight swooping in to save the day!

Each method has its pros and cons:

| Method | Pros | Cons |

|---|---|---|

| Frost Fans | Automated, low-maintenance | Can be noisy |

| Wind Machines | Automated, low-maintenance | Can be noisy |

| Helicopters | Versatile | Expensive |

These technologies work tirelessly to ensure apple blossoms survive those tricky spring nights, paving the way for a bountiful harvest later in the year.

Hail Nets and Cannons

Hail nets and cannons are the dynamic duo protecting apple orchards from the brutal bashing of hailstorms. These high-tech defenders ensure our apples remain unblemished gems of the season.

Hail Nets

Hail nets are like giant shields stretched over orchards. These tough yet light meshes intercept hailstones before they can damage the fruit below. They're engineered to block hail while still allowing sunlight, rain, and air through – essential for the apples' growth.

"While the initial setup is costly, hail nets are a solid investment. They protect the crop from devastating hail damage, ensuring growers can continue to fetch premium prices for their top-notch apples."

Hail Cannons

Hail cannons, on the other hand, are straight out of a sci-fi movie. These contraptions blast sound waves skyward to shatter forming hailstones in the clouds. When activated, they emit powerful shockwaves that disrupt the growth of hailstones, turning potential ice missiles into harmless raindrops.

However, hail cannons aren't silent guardians. Their booming 'shots' can be quite noisy, potentially causing neighborhood disturbances. They're also a significant upfront investment, but can save a substantial portion of a grower's annual revenue in the long run.

Both technologies are testament to the lengths apple growers go to protect their crops. Thanks to these hail-defying heroes, our apples have a better chance of reaching us in perfect condition, preserving their journey from blossom to bite.

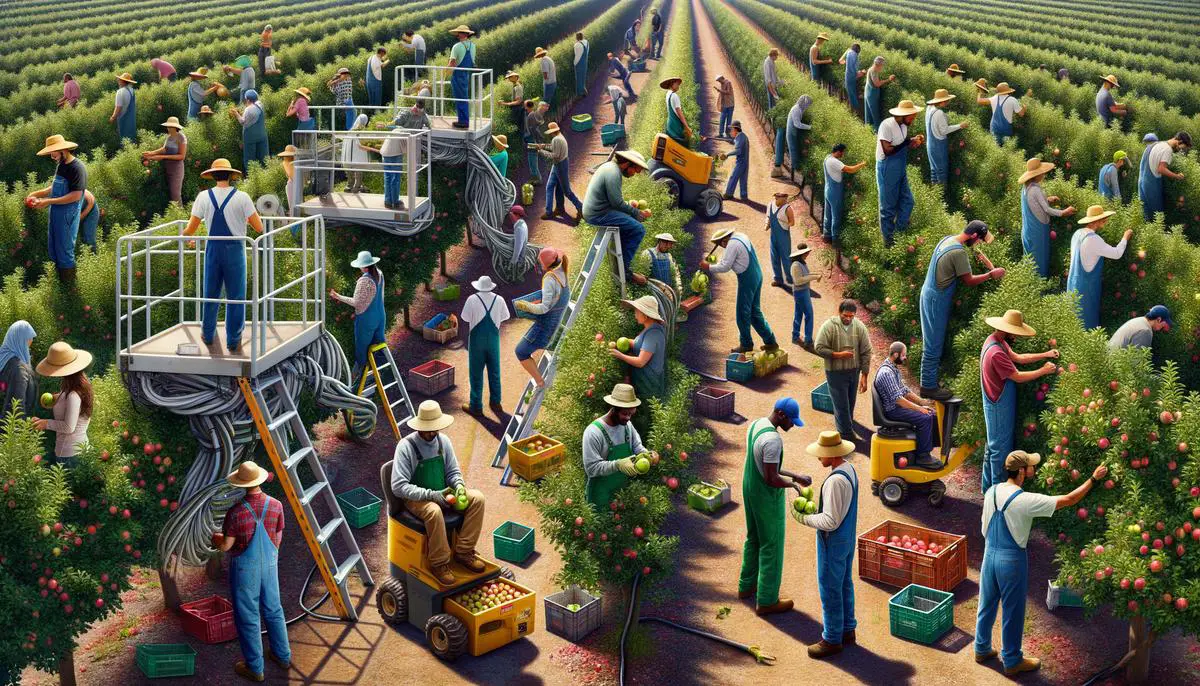

Automated Platforms and Picking Robots

Gone are the days of apple pickers balancing on ladders. Now, automated platforms and picking robots are revolutionizing orchards. These platforms glide between tree rows, lifting workers to the perfect height for each task. It's like having a personal elevator in the orchard – convenient and safe!

These self-steering, self-propelled platforms move through orchard rows with precision, ensuring consistent speed for uniform pruning and thinning. It's a huge leap from traditional hand-picking methods.

But the real showstopper is the picking robot. Picture a mechanical marvel with multiple arms, gently grabbing apples with suction cups. These robopickers use high-tech sensors and cameras to identify ripe apples, picking them with ninja-like precision.

Field tests of these robots are underway in central Washington. Growers are buzzing about potential labor efficiencies and cost savings. Imagine robots working round the clock, tirelessly picking apples with the finesse of a gourmet chef.

Innovative Robotic Solutions

- Advanced Farm: A California-based robotics company developing apple picking robots with multiple arms and gentle suction cups.

- Tevel Aerobotics: Offers flying drones that use tiny rods and suction cups to carefully extract apples.

- Washington State University: Researching robotic arms capable of tasks like trimming apple blossoms.

With labor costs rising and younger generations shying away from tough harvesting work, robotic picking solutions offer hope. This technological embrace promises to plug the labor gap while elevating the efficiency and precision of apple harvesting to new heights.

Machine-Based Fruit Tracking

Machine-based fruit tracking is like giving apple growers a high-tech crystal ball. It provides insight into the exact number and size of apples right on the trees. Imagine striding through rows of apple trees, knowing exactly what each one is yielding, thanks to an ATV-mounted scanner.

In Washington State, growers are testing this fantastic technology. Picture an ATV gliding down orchard rows, armed with a sophisticated scanner. This cross between a road warrior and a scanning superhero captures detailed images, counting and sizing apples as it buzzes along.

Benefits of Machine-Based Fruit Tracking:

- Data-driven decision making for crop management

- Maximized fruit prices through precise sorting and marketing

- Efficient resource allocation

- Yield prediction and size forecasting

"This foresight is a game-changer in forecasting revenue and planning labor needs."

Implementing such advanced technology requires an initial investment and a bit of a learning curve. But over time, the savings in labor costs and the boost in profitability make machine-based fruit tracking a no-brainer choice for savvy apple growers dedicated to staying ahead of the game.

Labor Challenges and Solutions

In the world of apple orchards, labor challenges are a constant headache. Growers are scrambling to keep up with rising labor costs and a shrinking pool of willing workers. But fear not! Technological advancements and the H-2A visa program are swooping in to save the day.

Apple picking and orchard management require both physicality and precision. Apples bruise easily and need skilled hands to handle them. This means human workers are still essential, despite technological advances. However, labor costs are skyrocketing, eating up to a fourth of all production costs in the U.S. apple industry.

The Robotic Revolution

Automated platforms whir through orchards, taking over laborious tasks and allowing human workers to focus on more skilled jobs. These self-steering, self-propelled platforms reduce the need for risky ladder work. Robotic arms swoop in to pick apples with the tenderness of a seasoned pro.

But automation isn't a magic solution. The upfront costs for these robotic systems can be eye-watering, especially for small orchard owners. Yet, the promise of reduced labor costs and higher productivity makes it a juicy long-term investment.

H-2A Visa Program

Alongside these mechanical marvels, the H-2A visa program addresses labor shortages by bringing in temporary foreign workers. It's become crucial for apple growers, particularly in top-producing states like Washington. The program requires growers to offer above-minimum wages, provide housing, and cover transportation – a hefty package that benefits both growers and workers.

Fun fact: Labor-intensive apples like Honeycrisp can take up to five passes through the orchard to pick due to their staggered ripening. Wages for pickers operating on piece rates can go up to $28 a bin.

The transition to this tech-empowered system isn't without growing pains. Older farmers sometimes resist the shift, while tech-savvy growers see robotics as a solution to long-standing labor shortages.

Economically, the impacts are enormous. With precise productivity tracking, efficient labor allocation, and reduced overhead costs, apple growers can see their profits rise alongside produce quality. Instead of labor shortages derailing harvests, robotic and H-2A interventions create a virtuous cycle of steady output and higher profitability.

So, next time you bite into a perfectly crisp apple, remember the blend of cutting-edge technology, human touch, and strategic labor policies behind it. It's a dance of humans and robots, innovating to preserve the tradition of apple farming while ensuring our apple-enthusiast hearts stay full and happy. 🍎